From Scrap Yard to R+E Cycles - Dan Towle's Story

By Amy Ensign - May 2007

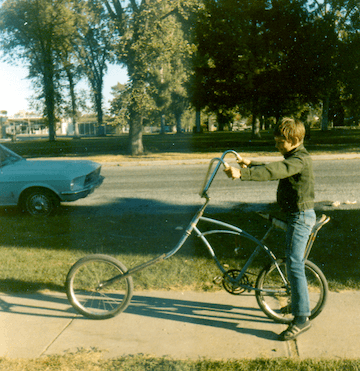

Dan Towle's chopper.

Photo courtesy of Dan Towle's mom.

AE: What fascinates you about bicycles?

DT: I don't know. I've always enjoyed them. I guess there's nothing more efficient than a person on a bicycle. It's only the human that powers it. I was fascinated by the Wright brothers [when I was a kid]; they sold and repaired bikes for a living. I always thought of them as bike mechanics who invented an airplane. All the models they made to test their wing design, they made out of scrap bicycle parts.

AE: How did you get started in cycling?

DT: I grew up in a small town - Jerome, Idaho. There was no bike shop; Western Auto was the place where people bought their bikes. My dad's gas station is where kids would bring their bikes to get fixed (tires, chains, etc.) When I was little, maybe eight or nine, I would spend the summer working at the gas station, my job was to fix any of the bikes that came in...

[Prior to] 1984 I was running a small bike shop during the summers in my hometown. I would take out a little ad for bike tune-ups, and I sold a couple of new bikes. And then when we got married, we decided we were going to move to Oregon and buy a bike shop and...after stagnating for a couple of years we were not able to save up any money, we ended up moving to Seattle because my mom was here. We stayed with her for a couple of months and then she actually moved back to Idaho. I just went to work here [R+E Cycles] , my wife worked in a construction company down the street. I really liked it because they made bicycles as well as repairing them. I was the service manager for three or four years. And eventually we ended up being in a position to buy the company in 1993. I wanted to make bikes the way I wanted to make bikes.

AE: How did you learn about manufacturing bicycles?

DT: By doing it. Most people that I know in this industry don't have a formal education. I was always buying bikes with friends and cutting them up and making stuff out of them when I was a kid. It was always a love. I have a friend down in Salt Lake...When he and I were in 5th or 6th grade we'd go down to the local scrap yard. There were bicycles people would just junk, and we would strip the parts off that we wanted and put them on scales (scrap is sold by the pound), bring them back to my house, and make bikes. He's doing that with his teenage boys now. And I'm doing this. He calls me for parts once in a while.

AE: What does a typical day at work look like for you?

DT: I'll be doing anything from working at the frame shop to fixing a computer that broke down... that was one of the things that really surprised me. When we got married and we wanted to move to Oregon and buy a bike shop, we didn't think that my job would be writing a newsletter, fixing a computer, writing software. I spend so much time doing that kind of stuff. When the summer really picks up I work a lot in the repair shop, that's where I really like to work. I'll work in the frame shop when I'm needed. Fitting bicycles, I really like to do that, I like to work with customers.

Dan Towle now.

Photo courtesy of Dan Towle.

AE: Why is fit so important when choosing a bicycle?

DT: It's the main thing that counts. If it doesn't fit right, you're just not going to ride it; it doesn't matter if it's a good deal or not. Nobody would go out and buy a pair of shoes that are two sizes too small just because they were on sale. Fitting a bicycle isn't something that people just learn in a training seminar. It's really one of those things that people that have done it for years can look at people on a bicycle and work with them. Feedback from a customer is probably your most important tool. If someone has a bicycle they don't feel that they can go out and ride for 50 miles without pain, they're just not going to ride it. I'd hate to see that.

AE: What would you consider to be your strengths and weaknesses?

DT: My weakness and my strength are probably the same thing. I have a hard time accepting if I can't do something. I tend not to be able to look at things and compartmentalize them. To me, whether it's writing a newsletter or building a bicycle or anything else, it really bothers me until it's done. I love the challenge. We were selling so many bikes, and it was taking so long to get them built. We were trying to build batches of bikes to save on setup time. If it takes 20 minutes to set it up, you might as well cut 10 [bikes]. Pretty soon you've got 40, 50 bikes all in various stages of not being finished. It took my adrenaline level through the roof.

Last winter, we had just built six triples. I went and pulled the plug. It was November 21st. I said, "We're going to stop. We're going to build every bicycle one bike at a time." This seemed impossible, because it would seem inefficient. Well, why is it inefficient? Why don't we eliminate the setup? How can we do it? This is the fun stuff, trying to solve a problem that no one has ever tried to solve. If we had a machine for each thing, it would eliminate setup time. We needed 12 machines. We didn't have room, these machines are huge, as big as refrigerators. They don't make small machines. So we decided we'd make small machines. We made all these little machines, but all they do is one thing. Everything is placed as close as we can get it together. We got it down to where we can produce four frames per day with two frame builders.

The weakness that comes along with that is not accepting what can't be done. I tried to hire someone to do the newsletter for me, and I couldn't describe how to do it. How do you get content? You just open the computer and start writing. She could do the layout, but then she needed me for the content.

AE: Where do you see R+E Cycles in 10 years?

DT: Hopefully right here doing the same thing we've been doing for 34 years. The bike industry seems to always support a good strong shop that knows road bicycles.

AE: What do you like best about running R+E Cycles?

DT: The customers. We really have great customers, they're just fun.

AE: Of all that you built, which one is your favorite bike?

DT: That's hard to say, I like all of them in their own way. I really like the new 14-pound steel bike that we make because it's completely against convention. It's a bike that everyone else says cannot exist. It's one of the lightest bikes in the world, it's a full, ready to ride bike, and it's made out of steel.

AE: What would you say to someone interested in entering into this field?

DT: Do it. Because if you love bicycles, that's really it. It's not a huge moneymaking venture. People that have tried in that way, they do fail. Be prepared to work 80 hours a week.